How To Calculate Plate Costs And Engineer Your Restaurant Menu

by The Ottimate Editorial Team

This is an editorialized guest post by our partner, COGS-Well, originally published here.

As restaurant operators, food costing and menu engineering is oftentimes a task that is done intuitively through simple spreadsheets or back-of-envelope calculations. While these may suffice for restaurants with two to three menu items, it becomes much more challenging as operators start to expand their menu offerings. Engaging in a structured and organized methodology to managing recipe costs, or plate costs, is a critical step to restaurant success.

In this article, we look at a couple of ways to manage and fine-tune your food costs for better profitability. The primary methods discussed are:

- Better Menu Engineering through recipe costing and menu analytics

- Using Inventory Variance Control to reduce inefficient ingredient usage

Recipe Costing: The First Step in Menu Engineering

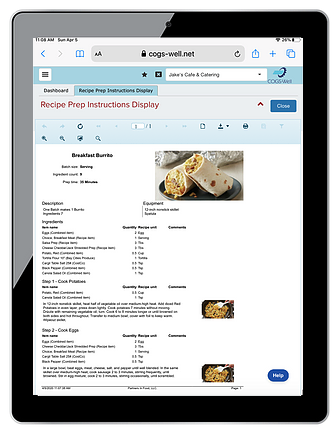

The first phase of menu management consists of building the recipes for prepared items and menu items. Once the recipe ingredients and portions are entered, a cost is calculated for each recipe.

What Is Recipe (Or Plate) Costing?

Recipe costing (also known as plate costs) is the cost of ingredients needed to make a single menu item. Engineering your menu for the right balance between quality and profit margin ultimately boils down to how you manage your ingredient costs. Recipe costing is an important part of this process as you try to break down bulk food purchases into individual menu items. It helps you to calculate your food cost percentage of your final menu price.

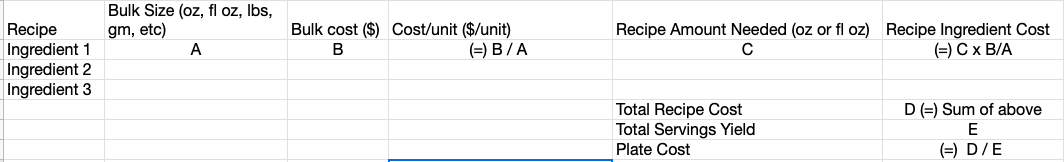

Here’s how you could do it manually (in very simple terms):

- First, review your recipe. A recipe ultimately boils down to a list of ingredients, quantities and the number of servings (yield) generated from the recipe.

- Then, using your inventory system, record the bulk size and cost of each ingredient. This will help you calculate the cost per unit of each ingredient.

- Then, using your recipe, multiply the amount of ingredients needed to construct your recipe by the cost per unit of each ingredient. This will then generate the final cost of your recipe.

- Divide the total cost of the recipe by the number of servings yielded to arrive at your plate cost.

This is a simple spreadsheet model that you could use. However, its always better to use a recipe management system like COGS-Well to do this at scale.

While recipe costing can be done using a spreadsheet like the one above, this approach is very difficult to maintain. Ingredient costs are constantly changing and recipes are often adjusted over time.

It is much easier to use a system designed for recipe costing, like COGS-Well, working together with an AP automation solution, like Ottimate, that automatically updates ingredient costs using invoice line items that are synced automatically from the AP platform.

COGS-Well allows you to enter a target cost percentage for a menu item and it will then suggest what the price should be to achieve your target. For example, if the recipe cost for a cheeseburger is $2.00 and your target food cost is 33%, then COGS-Well will suggest to price the hamburger at $6.00. Without this practice, It will be difficult to achieve financial success if you don’t begin with pricing that is targeted for that success.

With COGS-Well you can also monitor how ingredient cost changes are impacting your target menu item prices and profitability. If a menu item cost becomes too high, you can model changes that bring the cost back down. These changes could be to price, portion sizes, or the type or source of an ingredient.

Menu Analytics: The Second Step in Menu Engineering

The next part of this process is syncing data from your point-of-sale system to your recipe management system to understand which menu items are selling the best.

In an ideal world, the best menu item is one that

a) sells the most, and;

b) has the highest profit margin.

Comparatively, the worst menu item is one that has both poor profit margins and poor sales. Menu analytics helps surface relevant insights like these that help you design and your menu for maximum revenue and perform menu engineering.

What is menu engineering?

Menu engineering, which is the practice of understanding and designing your restaurant menu for maximum profitability.

Menu engineering has two main methodologies:

Menu design — By designing your menu to prioritize higher profit items that sell better, you can influence consumer choices psychologically. For example, featuring your highest profit margin dish as the first or second item on the menu (or displaying a picture of the dish on the menu) psychologically nudges customers to pick that item.

Plate Construction — By understanding your plate costs and breakdown by ingredients, you can construct your plate to balance costs against popularity to improve the profit margins of your menu item. For example, featuring grains or vegetarian ingredients at the center-of-plate appeals to health-conscious consumers but also has the added benefit of being lower in cost than meat or seafood.

Using Variance Control To Reduce Inefficient Ingredient Use

In an ideal world, as a restaurant owner you would want to use a 100% of ingredients purchased in menu items sold. Of course, that would never happen, as a lot of food ingredients end up being discarded due to waste, spoilage and so on. This may seem like a herculean task to achieve, but the process and methodology itself is pretty simple.

The answer to this problem is inventory usage variance control. Once recipes are created for each menu item and the sales mix is imported from your POS, a recipe management system helps determine how much inventory you should have used and then compares it to the quantity actually used to identify variances.

Here’s how it works:

Start by calculating how much inventory should have been used (theoretical usage) for each inventory item by looking at the recipes the item is used in, the portion size, and the number of times the recipe is sold.

Theoretical Usage Of Ingredient =

Sum Of (# of times menu item is sold (x) quantity of ingredient in each menu item)

For example, if a cheeseburger has a six-ounce portion of ground beef, and it is sold 100 times, the theoretical usage of beef works out to about 600 ounces of ground beef (37.5 pounds).

Next, you can calculate actual usage for each inventory item by using the accounting standard formula:

Actual Usage =

Beginning Inventory Count (+) Quantity Received (-) Ending Count

Using the cheeseburger example, if you started with 10 pounds of ground beef, and received 40 pounds, and you ended the period with 8 pounds, then your actual usage of ground beef is 42 pounds.

By comparing the 37.5 pounds theoretical usage for ground beef to the actual usage of 42 pounds, an inventory control system will calculate a usage variance of 4.5 pounds.

The difference here could be spoilage, over-portioning, waste, or other causes, but because you have been able to identify the source of the variances, you now have the ability to hone in on those ingredients and identify ways to reduce wastage.

While its relatively easy to track these variances for one to two menu items, it will quickly become harder once you add more menu items. That’s why its a good idea to use a recipe management system like COGS-Well to help track theoretical costs and variance for scores of ingredients.

Conclusion

The combination of menu management and inventory variance control is commonly referred to as performing “Food and Beverage Cost analysis.” Food and beverage cost analysis can be done most efficiently by using an inventory control and menu management system like COGS-Well that is designed to deliver these features.

While food and beverage cost analysis does require taking the time to set up and maintain recipes, the effort is primarily a one-time effort and the return can be significant both financially and operationally.

Ottimate integrates with COGS-Well so you can sync invoice line items of ingredients purchased directly to inventory tracking so you can effortlessly calculate and engineer your menu with minimal manual data entry.

Learn more about our partnership here!

Stay up to date on the latest news in AP automation and finance

Related